Welcome to Webinar Efficient Paper Machine Dewatering

SPEAKER: Jussi Lahtinen, Sales Director, Runtech Systems

WHEN: Wednesday, April 19, 2 PM CET

LANGUAGE: English

PLATFORM: Zoom

Fill out this short form to register!

A well-designed doctoring system is the key to a well performing and energy efficient press section. Optimized doctoring leads to increased dryness after the press section. Savings in dryer section steam usage are notable. Save-alls result in higher dryness after press, better moisture profiles, less steam consumption and reduced draw from press to dryer.

The effects of efficient dewatering are significant. The increased dry solids content after the press improves web wet strength, making the web stronger and allowing it to withstand unstable conditions in the drying section. This, in turn, is directly related to dryer section runnability, since good tensile strength reduces web breaks and improves end product quality.

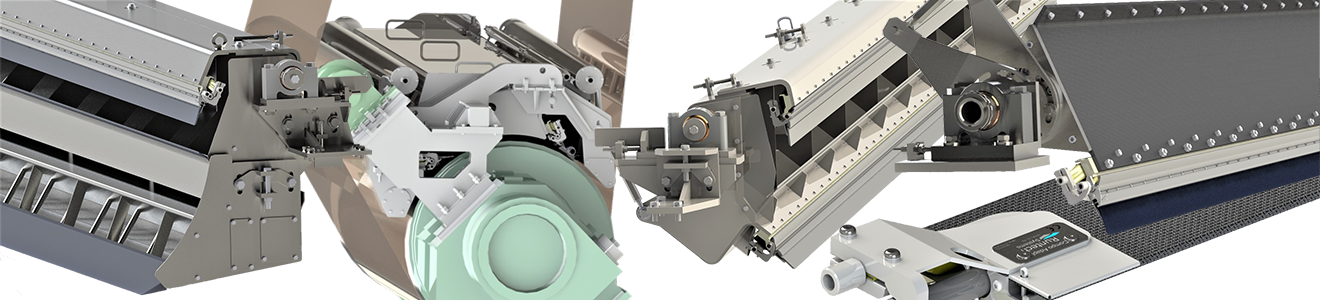

PAPER MACHINE DEWATERING AND CLEANING SOLUTIONS

Runtech's RunDry solution consists of savea-lls, doctoring, forming and dryer section cleaning systems and EcoFlow dewatering measurement system. RunDry significantly improves dewatering, doctoring and cleaning processes enabling increased dryness after the press section. RunDry is a complete solution with the payback time typically under 1 year.

Visit our website www.gardnerdenver.com/runtech

© 2025 Ingersoll Rand | 525 Harbour Place Dr. | Davidson, NC 28036 | USA

Legal Information

© 2025 Ingersoll Rand

© 2025 Ingersoll Rand