Faster, More Accurate Assembly For Solar Plants

Need to see QX Connect Series™ tools in action for

solar power plant?

Just get in contact with us to talk about a field trial close to you!

3 OPERATIONS.

1 TOOL.

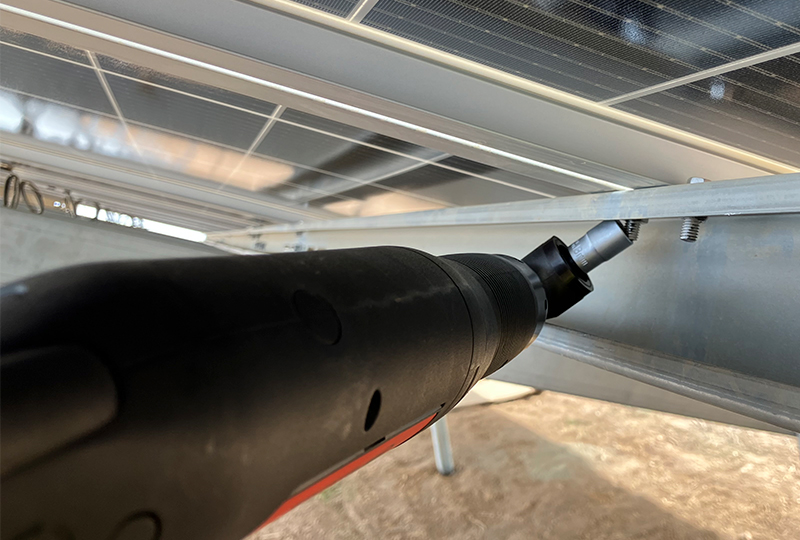

Tightening + Torque Fine Tuning + Control = QX Connect Tool

x5.3 times faster tightening with torque control

RIGHT FIRST TIME.

EVERY TIME.

Cut quality & overtorque related costs

ACCESS ANY BOLT.

ANYWHERE.

94% less workload in compact PV cell tightening

PAIN: Massive working load

With hundreds of thousands of bolts in the average array – and arrays growing all the time – a complex, labour-intensive tightening process means lost time, lower productivity and increased cost.

Our Solution:

Set the expected torque level on every tool using our mobile app or the display on each tool. Then you’re ready to go, with accurate tightening every time.

PAIN: Overtightening

Checking and adjusting every bolt tightened with simple tools costs you time and money.

What’s more, an average 20% of bolts are overtightened, risking deformation of panels, structures and bolts… and even higher costs.

Our Solution:

QX precision tools with their torque control system and transducer are accurate to around 3% every single time. That means more quality and lower costs due to overtorque deformations, penalties and customer complaints.

PAIN: Difficulties to access bolts

With today’s smaller, more compact PV cells it can be hard to access bolts using standard assembly tools. Manual adjustment is time-consuming and fiddly, and can cause expensive damage.

Our Solution:

With their unique crowfoot, specially designed for solar applications, QX precision tools give you access to every joint – even in the most compact structures.

Visit our website www.ingersollrand.com

© 2024 Ingersoll Rand | 525 Harbour Place Dr. | Davidson, NC 28036 | USA